The chemical industry is at a turning point, and Copernic Catalysts is building the technology to lead it—next-generation catalysts that reduce costs, lower emissions, and unlock step-change efficiency. Over the past year, our partnership with Schrödinger has led to significant breakthroughs in catalyst design, particularly in ammonia synthesis. With clear momentum and a strong technical foundation, we’re now scaling toward full commercial deployment.

A Breakthrough in Ammonia Synthesis

Ammonia production is a cornerstone of the global chemical industry, with approximately 180 million tons produced annually to manufacture synthetic fertilizers and industrial chemicals. However, this essential chemical accounts for around one percent of global CO2 emissions. If the industry can reduce the temperature and pressure of ammonia production, we can simultaneously decrease ammonia’s cost and carbon footprint. This may enable new applications of ammonia to compete economically, leading to the adoption of ammonia as a zero-carbon fuel for shipping and a carrier for hydrogen. The keys to making this vision a reality are improving production efficiency and reducing capital costs, and our breakthrough catalyst is a significant step toward addressing this need.

Ammonia synthesis catalyst technology has remained essentially unchanged for over 100 years. Existing catalysts are still primarily composed of iron ore and are refined using the same techniques developed in the early 20th century. While incremental improvements to performance have been achieved, the industry has struggled to make a significant leap forward — until now.

“Copernic’s ammonia catalyst breakthrough—which makes ammonia production cheaper, faster, and cleaner—is a powerful example of how science and computation can yield world-changing innovation,” said Nima Ronaghi, Principal, Breakout Ventures.

Through our collaboration with Schrödinger, we have developed a world-class ammonia synthesis catalyst that is significantly more productive at lower temperatures and pressures, resulting in substantial energy savings and reduced construction costs for the plant. Our models indicate that our catalyst can reduce energy consumption for ammonia production by up to 47 percent, translating to savings of tens of millions of dollars per year for large-scale ammonia plants, with payback periods as short as two to six months.

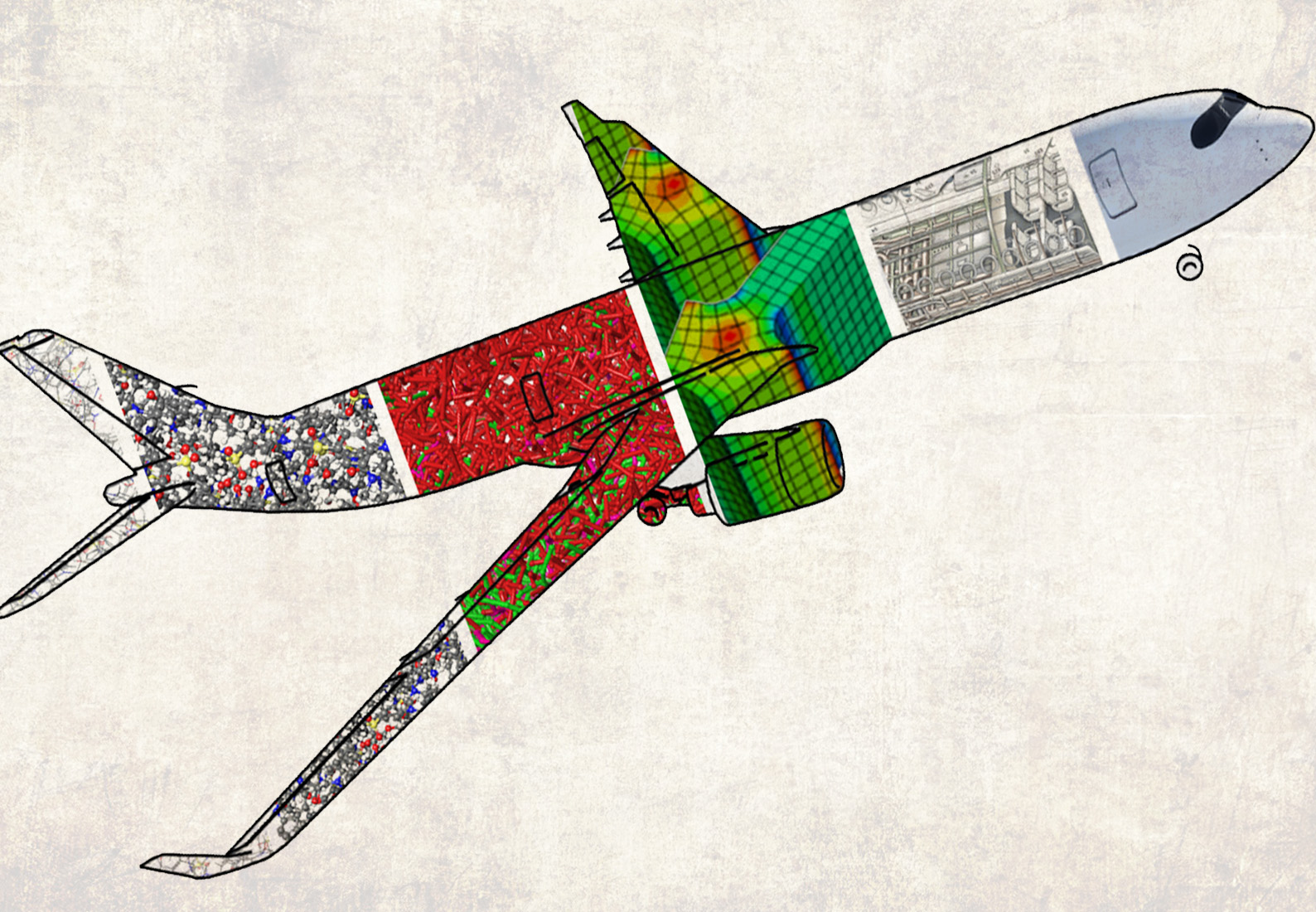

The Power of Computational Catalyst Design

Ammonia is a relatively simple molecule, composed of one nitrogen atom and three hydrogen atoms. However, an ammonia catalyst is a highly nuanced material, where even minor changes in the composition of its elements can dramatically alter its performance. There is massive complexity in the interactions between nitrogen and hydrogen gases and the solid catalyst surface. This complexity and the infinite number of possible material combinations make it difficult to refine an improved catalyst design using traditional trial-and-error methods. That’s where computational modeling, powered by Schrödinger’s advanced simulation methods, have proven invaluable, tilting the odds in our favor by enabling a more rational approach to molecular design.

While the chemical industry is traditionally cautious about adopting new technologies, the early feedback on our catalyst has been overwhelmingly positive. Industry experts who have reviewed our data describe our performance as the best they have seen. This validation gives us confidence as we scale and prepare for commercialization.

Next Steps for our Catalyst Portfolio

Copernic recently completed the Seed Prime funding round, raising $8 million with Schrödinger as a continued investor. These funds fuel our efforts to scale our ammonia synthesis catalyst from the gram to the kilogram scale, with the ultimate goal of full-scale commercial deployment. We have already secured a partnership with one of the world’s top five ammonia producers, who will be benchmarking our catalyst against their existing solutions in 2026. We successfully demonstrated catalyst stability at the lab scale, and the next step will be a larger-scale pilot, which will soon lead to full-scale deployment in industrial plants. Note, the catalyst market is $30-50 billion by 2030.

Building on the success of our novel ammonia synthesis catalyst, we are now expanding our collaboration with Schrödinger into a second catalyst for another high-value chemical. Just as we did with ammonia, we believe we can leverage computational design and high-throughput experimentation to develop a catalyst that dramatically lowers both production costs and carbon intensity. We are at the beginning stages of this effort, but our prior success gives us confidence in our approach.

Building a Portfolio of Catalysts for Increased Efficiency

We are at an inflection point in the chemical industry. Industry and agriculture rely heavily on chemical feedstocks and fuels. To make these sectors more sustainable, it is essential to reduce the energy intensity of chemical manufacturing and make sustainability more economically viable. At Copernic, catalysts are the linchpin in this transformation.

In partnership with Schrödinger, our mission at Copernic is to develop a portfolio of catalysts that accelerate the chemical industry’s transition to a more sustainable future. We see vast opportunities in many critical areas of sustainable chemicals, such as agriculture and green fuels. As we continue to expand our portfolio, our vision remains clear: to enable the chemical industry to become more efficient, sustainable, and cost-effective.